|

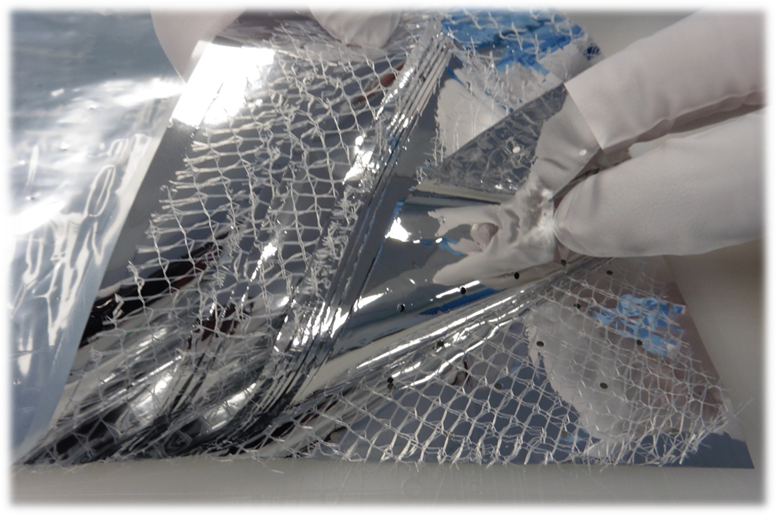

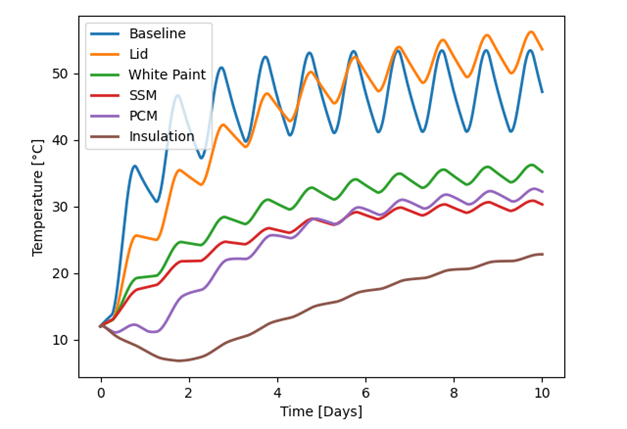

A project supported by a STFC Food Network+ (SFN) Scoping Grant has found that borrowing solutions from space technologies could make a dramatic difference in reducing food loss in developing countries. Reducing food waste is an urgent challenge, both to achieve food security for the growing global population, and to help us reach net zero carbon emissions. Often, the focus is on consumers but in developing countries around 90% of food wastage occurs in the supply chain, before products even reach the market. A key reason for this is a lack of refrigerated storage and transport. India, for example, has the sixth largest food and grocery market in the world, yet up to 40% of harvested crops are lost before they can be sold to consumers . With so much of the population dependent on agriculture, these loses keep many rural communities trapped in poverty. ‘Addressing post-harvest food losses in developing countries offers enormous potential to increase food security in these regions’ says Dr Bryan Shaughnessy, head of the Thermal Engineering Group at STFC RAL Space. ‘With such large volumes being lost daily, solutions that make even a small difference will translate into many tonnes of food being saved.’ Although his day job is to design thermal control systems for scientific spacecraft, Bryan became interested in the issue of post-harvest food loss when he attended an SFN meeting in 2017. ‘Talking to other attendees it became clear there was an enormous opportunity to reduce food waste in developing countries by providing cost-effective methods to keep food cool’ says Bryan. ‘It was also apparent that the technology and expertise I apply in developing instruments for use in space missions might bring a new and useful perspective to the problem.’ This led to Bryan being involved in an SFN pilot study in 2018 to consider options to reduce food loss in India. The transforming power of space technologies In this latest work, funded by an SFN Scoping Project Grant, RAL Space partnered with Go4fresh, an Indian fresh produce agritech venture, to explore whether space thermal technologies could potentially help design cost-effective and efficient portable cold storage units for foods in transit. Although space rockets and fresh produce may seem worlds apart, they both face the same critical challenge, as Bryan explains: ‘One of the key factors that accelerates food spoilage is large variations in temperature, particularly in developing countries which may have long, highly fragmented supply chains combined with tropical climates. Similarly, spacecraft experience an extremely hostile thermal environment, which ranges from the extreme cold of deep space (around -270°C), to intense heating from the Sun.’ Without careful thermal control, spacecraft simply wouldn’t be able to survive these extreme temperature fluctuations. Consequently, engineers such as Bryan investigate how to exploit the physical properties of materials to keep these instruments within a safe temperature range. These methods include using highly-reflective surface finishes and insulation materials with low thermal conductivity. Because these technologies are typically lightweight and passive – not requiring a power source – they are particularly suitable for areas without a robust energy infrastructure. For this study, the team focused on tomato production in Nashik, a district in Maharashtra state. With tomatoes having one of the highest percentage losses (around 12%) across vegetables in India, even a small reduction in waste would result in significant savings. Capturing the temperature profile of a tomato in transit The first step was to develop a simple thermal model to better understand the heat transfers that tomatoes experience during their journey from the farm to market, via various distribution centres and wholesalers. This was crucial to understand the most important factors that affect how quickly tomatoes spoil, and therefore the requirements that a portable cold chain container would have to meet. ‘Developing this model was actually quite a challenge, because we were adapting software that was designed to predict the temperatures of satellites in the vacuum of space’ says Bryan. ‘Some additional research was needed to better understand the weather conditions in Nashik and find a way to represent this in our model.’ A simulation was then run to represent a ten-day period - a typical transit time for tomatoes destined for non-local markets. The target at this stage was to keep the produce below 25°C throughout the journey. Simple changes, significant effects For the baseline scenario, where the tomatoes were transported in open crates, the model indicated that the tomatoes experienced wide temperature fluctuations, reaching a maximum temperature of around 50°C. Even before technical solutions were considered, the analysis demonstrated that simple modifications could make a dramatic difference. Painting the outer surfaces in white paint, for instance, reduced the temperature fluctuations and the maximum temperature to more like 35°C. ‘This might sound like a simple solution, but white paint is often used as a surface treatment for spacecraft thermal control because of its low solar absorptivity and high infrared emissivity. This means it radiates away more heat than it absorbs from the Sun,’ says Bryan. The team next investigated the impact of coating the exterior of the box with a finish called a Second Surface Mirror. Like white paint, these thin, transparent materials reflect a high proportion of sunlight but can radiate heat in the infrared, and are often used on spacecraft as part of a passive thermal control system. This performed a little better than the white paint, causing a slight further reduction in temperature. ‘Although Second Surface Mirrors are routinely used on spacecraft, this is interesting because it might be possible to make a similar ‘solar reflective’ sheet using locally-available materials’ Bryan says. Adding a coolant material, such as an ice pack, also had a significant effect, and kept the tomatoes within safe temperature limits for four days, doubling the time they could be transported. However, the benefit only lasted until the ice pack thawed, and relied on power being available to freeze the ice pack in the first place. The packs also presented the risk of causing chill damage to the tomatoes if they came in direct contact. Another idea borrowed from space technologies was to add a layer of insulation to effectively decouple the interior of the box from the external environment. Virtually all spacecraft are insulated using blankets made of multiple layers of reflective sheets interleaved with netting. But since these materials aren’t readily available in India, the team instead modelled a scenario where the tomatoes were packed with straw. Incredibly, this achieved a 10°C temperature difference between the inside and outside of the crate, and reduced the maximum temperature experienced by the tomatoes to under 25°C. The greatest benefits, however, were achieved when these approaches were applied in combination: the outer layer of white paint or a Second Surface Mirror, an inner insulation layer, and an ice pack. In this scenario, the tomatoes experienced no temperature fluctuations and stayed underneath 22°C throughout the ten-day period. Predictions from simplified model for tomato temperatures over time. Initial temperature 12 °C. (credit: RAL Space) Key: 1. Baseline: Tomatoes are packed in green coloured open top crate 2. Lid: As 1 with addition of green coloured lid 3. White: As 2 but external finishes white 4. SSM: As 2 but external finishes are Second Surface Mirror 5. PCM: As 2 with phase change material added 6. Insulation: As 3 with phase change material added and crate insulated Going Forward

‘Using the simple model, we demonstrated that improvements are possible using ideas from spacecraft thermal engineering’ says Bryan. ‘The challenge going forward is to develop these into systems that work on the ground and use readily available materials.’ In the near future, the team intend to carry out simple field trials to assess whether similar results can be achieved by retrofitting containers using only locally-available materials. ‘I am excited to be able to apply what I have learnt in my day job to contribute towards addressing global challenges’ Bryan concludes.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

AuthorJune 2024 - Archives

June 2024

Categories |

- Home

- Webinars and Events

- About the SFN+

- News

- Blog

- Expert Working Groups

- Funding

-

Publications

- Bioeconomy positioning paper

- SFN+ 5th Annual Conference

- OMM Policy Report

- ‘Multi-Stakeholder International One Day Workshop on Organic Agri-Food Value Chains for Net Zero’ Report

- SFN 2050 UK Net Zero Food report

- Sustainable Cold Food Chain Booklet

- Food Sensing Technologies for Safe and Nutritious Food

- Sustainable urban and vertical farming

- Projects

- Join/Contact Us

RSS Feed

RSS Feed