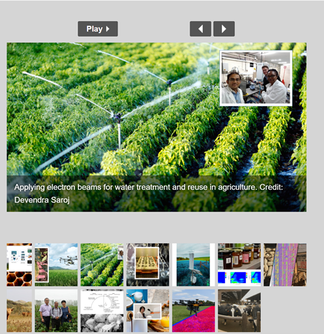

Using social media data to explore how the COVID-19 pandemic impacted consumer attitudes to food19/1/2023 COVID-19 shook global food supply chains to the core – but did this result in any long-term changes in societal attitudes towards food? A project funded by the STFC Food Network+ (SFN) combined the power of machine learning approaches with large-scale Twitter data to find out. The COVID-19 pandemic impacted every aspect of our lives, with food being no exception. For instance, as countries went into lockdown and panic buying swept supermarket shelves bare, many people experienced food insecurity for the first time. And whilst communal meals and eating out became impossible, online shopping and home meal preparation kits soared in popularity. Meanwhile, the sudden increase in home cooking led to greater interest in the health and nutritional attributes of what we eat. But now that most countries are returning to ‘near normality’, it remains unclear what the long-term repercussions of the pandemic will be. Did these sudden societal changes result in any long-term fundamental shifts in our purchasing behaviours and attitudes towards food? Understanding this could help policy makers to identify the most important food supply concerns of consumers during a crisis situation, which could inform strategies to respond to future emergencies. Twitter: an ideal tool for research To investigate whether consumer attitudes towards food were affected by the pandemic, a project backed by the SFN used machine learning methods to mine food-related information contained within social media posts on Twitter. With more than 500 million users worldwide, Twitter has become a global tool for sharing news, expressing opinions, and interacting with others in real time. This makes it highly suitable for capturing large amounts of organic data to explore sentiment and attitudes surrounding food concerns both before and during the COVID-19 pandemic. “Public attitudes on Twitter have already been used to evaluate consumer perceptions towards brands, predict stock market fluctuations, and assess the success of political campaigns” said project lead, Mohammad Delgosha, Associate Professor in Business Analytics at the University of Birmingham. “But up to now, little attention has been given to the feelings and perceptions of consumers regarding the unique and sheer scale of the impact of the COVID-19 pandemic on food supply chains.” Mohammad’s research focuses on data mining, specifically analysing Big Data by employing machine learning techniques to large amounts of unstructured data to find solutions for social, environmental, cultural and practical challenges. In the past, for instance, Mohammad has used textual Big Data to investigate the positives and negatives of automated algorithms being used to manage gig workers in digital platforms such as Uber or Deliveroo. According to him, Twitter data is highly useful for exploring consumer opinions in an unbiased way. “When we use surveys to try and assess consumer sentiment, these are inevitably constrained to the researcher’s existing knowledge or speculation. Twitter, on the other hand, offers significant amounts of open-ended data to explore open-ended questions” he said. Capturing meaning from Big Data The first stage of the project involved capturing tweets generated during two 16-week periods: from 7 August to 8 December 2019, and then the 16 weeks immediately after the World Health Organization declared COVID-19 as a global pandemic on 11 March 2020. By applying search algorithms to Twitter’s Application Programming Interface, posts were extracted that contained keywords related to food (for instance, food, crop, fruits, vegetables, meat, milk, and groceries) or supply-related terms (such as supply, chain, logistics, systems). This resulted in a dataset of around 182,000 tweets from 109,600 different people before COVID-19, and 427,000 tweets from 183,000 people after the lockdowns started. The sheer size of this dataset meant it would have been impossible to manually analyse it using human coders. So Mohammad used two natural language processing techniques, called topic modelling and sentiment analysis. “Topic modelling is an unsupervised statistical method for discovering abstract ‘topics’ within textual data. Its principal function is to combine main concepts within a text into a single, understandable structure” said Mohammad. This method scans the collection of text to detect frequently used words or phrases, and groups them to provide a summary that best represents the information in the document. Sentiment analysis, on the other hand, is a tool used to understand the emotion, opinion, or judgment behind written or spoken language, and to evaluate if this communicates a favourable, unfavourable, or neutral message. Businesses, for example, often apply sentiment analysis to customer comments or online reviews to assess how their customers feel about their product, services, or brand. The impact of COVID-19 on consumer concerns about food “Our results indicate that the public sentiment and topics associated with food systems were markedly transformed by the COVID-19 pandemic” said Mohammad. The sentiment analysis, for instance, showed that overall public attitudes towards food had a more negative tone and became more pessimistic during the initial COVID-19 wave, compared with before the pandemic. For instance, before the pandemic, around 47% of tweets had an average positive sentiment, with 36% being negative, and 17% neutral. During the first phase of the pandemic, however, the proportion of negative tweets jumped to 54%, with 24% being positive and 22% being neutral. Meanwhile, the topic modelling analysis found that the type of food-related concern also changed dramatically. “Before COVID-19, people were concerned more about social and environmental issues such as climate change, ethical concerns, children and healthcare, organic food, animal welfare, and diets” Mohammad explained. “From March to July 2020, however, food insecurity concerns significantly increased, becoming the main concern for the public. In addition, food donation, panic shopping, and the healthcare of workers in the food supply chain became other important concerns during the pandemic. This indicates that policy makers should focus on sustainable food systems and take actions for designing and implementing diverse and resilient food networks, especially for managing global shocks like COVID-19.”

Looking forward Despite this being the first time Mohammad has used Twitter data within a research project, he is already planning future investigations using similar methods. “Working on this project with the SFN has opened a new chapter for my research profile to continue using textual data from Twitter to answer important and fundamental questions about food supply chains, especially understanding and modelling food security issues in the UK or globally” he said. “Currently, my colleagues and I are working on two different research projects utilizing Twitter data for supply chain management purposes and analysing complaint management by businesses.” Mohammad would like to thank Nastaran Hajiheydari, Senior Lecturer in Digital Marketing and Analytics at Queen Mary University of London, for his help in collecting and analysing the Twitter data for this project.

0 Comments

A project supported by the SFN aims to empower smallholder farmers in India to become citizen scientists and champions for healthy soils, using a simple tool developed for mobile phones.

‘Across the world, it is the millions of smallholder farmers who are the ones working the soil. Unless we involve them and develop tools that they can easily understand and use, we won’t be able to help soils recover.’ Rajneesh Dwevedi. When it comes to food security, the focus tends to be on what is happening above ground rather than below our feet. But this needs to change – and fast. Worldwide, a third of agricultural soils are thought to be moderately to highly degraded (FAO), limiting their productivity. Besides putting millions of livelihoods at risk, global soil degradation also has significant impacts on climate change by releasing vast quantities of carbon to the atmosphere. A key characteristic of healthy soils is that they are highly biodiverse: teeming with life that ranges from microscopic organisms, invertebrates such as nematodes, insect larvae and earthworms, and mammals, reptiles, and amphibians. All of these play a fundamental role in maintaining the benefits of soils that we depend on. For instance, as part of their metabolism many microorganisms transform essential organic and inorganic compounds into forms that plants can use. Larger species, meanwhile, such as earthworms, ants and termites, engineer soil structure through their movements and open up pores for water and gas to flow. But modern intensive farming methods can have devastating impacts on soil biodiversity. Widespread use of pesticides and fertilizers, compaction from heavy farm machinery, and disruption to soil structure from ploughing devastate the complex webs of life below ground. This results in less efficient nutrient cycling, poorer soil structure and ultimately smaller harvests. It is a vicious cycle: as soil biodiversity decreases, agricultural productivity decreases – causing farmers to resort to even more intensive farming to try and maintain yields. In contrast, lower impact and regenerative farming methods – such as organic farming and ‘no-till’ farming – can maintain and even restore soil biodiversity. Wider adoption of these could help us start to reverse the perilous conditions of our soils, but a major barrier to this is a lack of ready tools and technologies to easily measure soil health. ‘Maintaining soil ecosystem services is a key challenge for sustainable food production, and one that depends on soil biodiversity’ says Mr Rajneesh Dwevedi (Lady Irwin College, Delhi). 'Achieving this will ultimately depend on the knowledge and actions of farmers. Though farmers often understand the importance of soil health, they are not able to monitor and infer the ecosystem condition accurately.’ As part of a SFN-backed collaboration with the STFC, Rajneesh is addressing this by developing an easy to use, intuitive tool for assessing soil health, designed to be suitable for farmers worldwide regardless of their level of education. To start with, he is focusing on India, where a large proportion of soils (particularly in the Gangetic plains) are severely degraded. Since the presence or absence of certain organisms can be a direct indicator of soil health, Rajneesh’s specific aim is to develop an accessible tool that can quickly identify soil species. Currently, existing guides for assessing soil biodiversity are often highly technical keys and charts, requiring expert knowledge to decipher. But Rajneesh’s vision is for a mobile phone application that uses the power of artificial intelligence to accurately identify soil species from photographs taken by the user. Having no previous experience of machine-learning approaches before, Rajneesh is working with Dr Melina Zempila from STFC RAL Space to refine the identification algorithms specific for soil organisms that will form the basis of the tool. In particular, Melina’s expert knowledge is helping to refine the method of classification using advanced image analysis based on information from the visible spectrum of light. But to train a program, you first need a labelled dataset it can learn from. Consequently, the first stage of the project saw Rajneesh travelling across North India between March and August 2022, collecting more than sixty soil samples from as many different farms as possible. This included both farms using intensive, pesticide and fertilizer-heavy practices and those based on organic methods. ‘It was a fascinating new experience to closely study so many different soils across India and to see how the biodiversity varied’ says Rajneesh. Back in the laboratory at Lady Irwin College, each sample was carefully analyzed and high- resolution images taken of the species to curate a database of labelled images. ‘Not surprisingly, our preliminarily observations found that soil biodiversity can vary significantly with soil type, with organic farms being richer than the conventional farms’ Rajneesh says. In July, Rajneesh visited the STFC RAL Space facility, based at Harwell, Oxfordshire, to meet Melina and discuss the next stage of the project: developing the identification algorithms. ‘It was a great experience to see the computing capabilities at STFC, and discuss the next stages of the project together. The initial results so far have been promising, with our prototype model being effective in identifying soil fauna present on the soil surface. Below ground species, however, remain difficult as they look similar in the visible spectrum.’ Another challenge will be to tweak the algorithms so they still work effectively on simpler, mobile-phone images rather than the high resolution photographs. ‘As a first goal, we hope this tool will enable farmers to become citizen scientists, capable of mapping soil biodiversity and collecting information simply by taking a photograph. A longer-term aim is that this information can then be used policy makers to identify priority areas for restoration. It could also help farmers to select the best crops for their fields, based on the soil health’ says Rajneesh. If successful in India, the method could be adapted to the soils of countries worldwide. Reflecting on his involvement so far, Rajneesh says: ‘I’ve really enjoyed working on this, particularly as it has motivated me to learn new things. My background is in biology, so artificial intelligence was completely foreign to me. Even so, I’ve found it a magical experience to get deep into the mathematics behind it. The SFN serves a great purpose in bringing people with different expertise together, to apply science and technology into making new solutions that ultimately help people.’ ‘People often assume that grater agricultural productivity always comes at the expense of nature, but I hope we can help show that these do not have to be mutually exclusive. There can be a middle way’ he concludes. Citizen scientists give major boost to SFN-backed project on anticipating food-system disruptions27/9/2022 Could social media help us prepare for future disruptions to food systems? Thanks to the help of over a thousand volunteers, a SFN-backed project is now close to finding out The past few years have demonstrated just how vulnerable our food systems are to large-scale disruptions, from pandemic lockdowns and social distancing to labour issues and extreme weather events. For the consumer, these can result in product shortages and empty supermarket shelves. Such uncertainty looks set to continue, as food producers start to feel the effects of climate change, and global political systems remain fragile. Consequently, a key part of the STFC Food Network (SFN)’s work is to research ways we can build resilience into food supply chains, so that they can keep functioning even when situations (and people’s shopping behaviour) change quickly.

Potentially, this could include harnessing the power of information contained in social media posts. One of the winning projects in the 2020 SFN Sandpit competition is investigating whether it could be possible to apply deep learning techniques to build a computer model that can forecast specific food-system disruptions (such as flour running out of stock) on the basis of the text and images that individuals post online (e.g. comments about flour). Project lead Dr Laura Wilkinson (Senior Lecturer in Psychology at Swansea University) explains the rationale: “The COVID-19 pandemic saw an unprecedented level of conversation around food on social media, with many people experiencing shortages of key staples such as flour for the first time. We suggest that understanding how people reacted during the pandemic may help us to understand what might happen to the food system if other events occur that lead to uncertain times.” The project’s ultimate aim is to train a machine learning programme to automatically detect patterns in people’s social media activity that indicate changes to food systems, and how consumers react to these. Training such a model, however, requires a detailed, annotated dataset, so that it can ‘learn’ which information is relevant to spot trends. To compile this, Laura and her colleagues created a database of just over a million anonymised Twitter posts, using searches with food-related keywords. The trouble is that some of these posts may not actually be about food at all, as Laura explains: “Many food words can also refer to other things. For example, the word ‘coconut’ could have been used to describe someone wanting to be able to eat a coconut or could have been used to describe their favourite shampoo scent. On the other hand, a tweet might be referring to food but not actually mention a food word like 'banana'. For instance, it might be referring to home deliveries and mentioning supermarkets. Unfortunately, computers are not very good at interpreting these situations.” This means that, in order to advance the project to the next stage, each tweet in the database first needs to be manually checked and classified as either being about food or not. As a small project team, this would have taken them an unfeasibly long amount of time… so they decided to call in reinforcements, by launching the project on Zooniverse! Founded in 2009, Zooniverse is perhaps the best-known citizen science platform, and gives any member of the public the opportunity to contribute valuable data for research projects. These typically involve categorising data that computers would struggle to do automatically, such as picking out animals in camera trap footage, transcribing historical documents, or identifying cell features from microscope images. For this project, participants were asked to read through the Twitter posts and decide whether they were about food or not. Since launching on Zooniverse in July this year, the response has been phenomenal. By the beginning of August, over 209,000 Tweets had been classified by 1,200 volunteers, reaching a high of over 36,500 classifications in a single day. But besides the raw data, Laura has been impressed by how the platform encourages dialogue between contributors and the research teams. “What makes citizen science projects distinct from many other research projects is that there is a high degree of knowledge sharing: the Zooniverse contributors are not passive participants” she says. “On the discussion boards for the project, participants have often reflected on what particular tweets mean to them and how they relate to their own food experiences during the pandemic. This really adds value to the study, giving us a much greater breadth of lived experiences.” The discussion boards also revealed how social and cultural differences can impact the understanding of food-related content, which could help inform the design of future studies. As Laura explains: “Our database is restricted to UK-located Tweets, but Zooniverse contributors are based all around the world. This has caused some questions about certain terms, for instance about the names of some UK supermarkets that aren’t widely known abroad, and whether Easter eggs in the UK are edible. The two-way discussion boards are a great feature, as they enable us to respond rapidly to these issues, and share information with the whole community of contributors.’ The team hope to start training the first machine learning model in September 2022. Once the workflow is established, Laura hopes it can be adapted to process information on an international scale and from different social media platforms. “I’m talking about Zooniverse to anyone who will listen – I think it’s an absolutely brilliant platform, which I definitely hope to use more of in the future” she says. “For instance, it would be very interesting to train an algorithm to classify photographs of meals that people post on social media for specific properties, such as the number of food components and portion size.” “As recent events have shown, we live in uncertain times and we can’t take our food systems for granted, presuming that we can always get exactly what we want from the supermarket, whenever we want” she added. “It is imperative that when global disruptive events occur, we have the information and the means to ensure that the most vulnerable people in our societies who may be food insecure aren’t hit the hardest.” A project supported by a SFN Scoping Award is exploring how virtual marketplaces could help smallholder farmers and microenterprises become more resilient to food-system shock The COVID-19 pandemic brought to light just how fragile food supply chains can be: with traditional trade disrupted, many producers struggled to find alternative routes to sell their products. Consequently, across the world shoppers were faced with empty shelves at supermarkets, even though farmers were having to throw away mountains of unsold produce.

Some of the worst hit were the many thousands of smallholder farmers and urban microenterprises trading fresh, perishable produce in low- and middle-income countries. Typically, these rely on in-person interactions at marketplaces, trade hubs and bazars, meaning that the COVID-19 lockdowns effectively shut down their trade. Sarang Vaidya, co-founder of fresh produce agritech venture Go4fresh, describes the situation in his native India: “Disruptions to traditional marketplaces during the COVID-19 pandemic resulted in extensive on-farm food wastages, unfulfilled demand, and major setbacks to the livelihoods of millions of small grocery shops, street vendors, and hawkers. If we want to help communities to become more resilient to future shocks, we need to provide access to alternative markets.” A marketplace on a mobile phone With mobile phones being almost ubiquitous across India, Sarang believes that one solution could be to create ‘virtual’ marketplaces that directly connect smallholder farmers to buyers (such as retailers, wholesalers, restaurants, and canteens). In 2019, this vision inspired him and his team at Go4fresh to develop a collaborative, digital platform to connect producers and businesses in food supply chains. However, currently very little is known about how such a platform should be designed to best meet the needs of smallholder farmers and microenterprises. To address this, Sarang is leading a SFN-backed project which is engaging end-users to identify the key data sources and features required to build a scalable, user-friendly virtual marketplace for affordable smartphone devices. The UK-India partnership involves experts in data science from STFC, besides a variety of Indian-based food-sector partners, including farmer groups and fresh produce buyers. The central objective was to build a prototype virtual marketplace for four vegetables (tomato, cabbage, okra, and green chilli) along an established trade route in India. This ran from the village of Otur in the Pune district of Maharashtra, to a market in the Kandivali neighbourhood of the state capital Mumbai (a distance of 200 km, or roughly five hours of driving). Through the Indian team’s links, the project consulted over 60 smallholder famers, microenterprise owners, and transporters. Due to ongoing COVID-19 lockdowns and social distancing restrictions, many of the interviews were conducted using phone/video calls or online chat functions. This qualitative research was supplemented with quantitative data, including live market prices, delivery dates, crop production data, and consumer prices on ecommerce platforms. Mapping the challenges against widespread adoption of digital technologies “We found that both the supply and market ends of the chain faced distinct challenges hindering the adoption of digital technologies” says Sarang. For those supplying fresh produce, a key issue was low current use of digital technologies, with less than a third using digital sources of information, such as market data and weather alerts. Another concern was that current data sources were often updated only infrequently, limiting their accuracy over time. In combination, this meant that smallholder farmers were often unaware of the current market prices for their products, resulting in them selling their goods for below-average price. Meanwhile, for the microenterprises purchasing fresh produce, the most prominent issue was the large variation seen among different lots of the same food product (including quality, weight, and packaging) and the lack of standardisation. This inconsistency meant that most traders visited the market every day to ensure they could access the best-quality products available. From their findings, the team mapped out the different variables currently influencing transactions between buyers and sellers, and used these to build a prototype digital marketplace. This also sought to address the low access smallholders currently have to pricing information by linking to benchmark markets with live data feeds. STFC co-PIs in the project Dr Jens Jenson and Dr Tom Kirkham, contributed their expertise in data architecture, selecting a platform and user interface, and effective use of data science & sensor technology. A promising prototype The result was an ecommerce platform designed to be resilient to network failures, provide strong data security, and be compatible with mobile devices. “The buyer interface has an end-to-end order management, with an integrated payment gateway. Meanwhile, the seller interface is a simpler version of a multivendor marketplace with features to add products, quantities, and target prices” says Sarang. “Based on over 300 transactions, we found that when farmers used the app to check the forecasted price for their product, this could increase their income by 15-22%, by helping them to find the best place to sell their products” he says. “This also enabled them to decide whether it was worth transporting their produce to the market in Mumbai to get a better price, or if they would receive the same amount at a local market.” In the future, Go4fresh envisages that the apps could also allow smallholders to capitalise on growing food trends, including the rising demand in India for healthy and nutritious food, besides food that is produced more sustainably. “Digital marketplaces can allow smallholder farmers to directly connect with the buyers who are most interested in their products, resulting in the best price for them and higher-quality products for consumers” Sarang says. For the next stage, the team will refine the template, based on input from a wider range of stakeholders covering different food products and supply routes. A particular aim is to simplify the interface and introduce an Indian language version for those with limited English. Ultimately, however, Sarang hopes this approach will have an impact far beyond India. “In many countries across South-East Asia and Africa, we see a similar scenario. If rolled-out at scale, digital marketplaces could help provide a more sustainable and resilient livelihood for millions of marginal communities” he concludes. Crop yields are affected by a huge range of different factors, which can make it immensely difficult to work out which set of conditions result in the best growth. But a project supported by the STFC Food Network (SFN) demonstrates that artificial intelligence and machine learning are promising approaches to reveal ‘ideal plant growth recipes’ hidden in large datasets. Farming already accounts for around 38% of the global land surface (Food and Agriculture Organization), but this will need to expand even further if current methods have to scale to feed the rapidly growing population. And with cultivated soils degrading at a frightening rate, agriculture is increasingly encroaching into pristine, biodiverse habitats. With ‘business as usual’ clearly being an unsustainable option, we urgently need to rethink the way we farm.

This has sparked huge interest in vertical farming, where plants are grown stacked in layers within a protected environment (typically indoors). In these soil-free systems, plant roots are either immersed in a nutrient solution (hydroponics) or exposed to the air and irrigated with a nutrient-rich mist (aeroponics). Vertical farming offers many benefits, including high space-efficiency, reduced water usage, shorter growing times, reduced need for pesticides/herbicides, and shelter from extreme weather. In addition, since vertical farms can be set up practically anywhere (even underground), they could enable hyper-localised production, thus shortening supply chains and providing fresh, nutritious food all year round. But there are currently many challenges with vertical farming, including high capital costs, considerable energy consumption and inefficient resource use. According to Chungui Lu, Professor of Sustainable Agriculture at Nottingham Trent University, a crucial first step to address these issues would be facilitating greater precision control of plant growing conditions. “Young crop plants are incredibly sensitive to a large range of different environmental factors, including air and water temperature, light, relative humidity, and CO2 levels” he says. “Even small differences can have a great effect on growth. However we currently have very little data on the optimum conditions for indoor farming systems.” With so many different factors affecting plant growth, it would be virtually impossible to manually work out the best combination in real-time to maximise yields. So as part of an SFN scoping project, Chungui joined forces with Dr Gadelhag Mohmed and Dr Steven Grundy from Nottingham Trent University, and Professor Wantao Yu (University of Roehampton) to explore how big data approaches could be used to derive ‘optimum growing recipes’. “Essentially we had two main questions” says Chungui. “Can we monitor in real-time all the factors that affect plant growth? And can we then use artificial intelligence, big data and internet of things methods to predict the conditions that give the best yield and quality for different crops?” The team’s approach centred on using neural networks, so-called because they mimic the way the human brain processes information. Structurally, neural networks are made up of a number of layers of nodes (neurones), each connected to nodes in the next layer. The connections between the nodes are weighted, and these weights are adjusted during a training process using a labelled dataset. The resulting network of connected neurones can then automatically (and accurately) process novel data to achieve the correct output. Traditionally, developing a neural network relies on prescribing important features within the training dataset, which requires expertise and can be time-consuming. But what sets deep learning apart is that the algorithm doesn’t need important features to be specified in advance: given enough labelled samples, it will discover the most relevant attributes on its own. “It would take forever to experimentally test each individual combination of the factors that affect plant growth, so being able to automatically infer this would be a tremendous advantage” says Chungui. But this intuition comes at the cost of considerable processing power: a single neural network can be made up of tens to hundreds of layers of artificial neurones connected by millions of weights, and in a single experiment go through over a billion computational operations. Since this is far beyond the capabilities of most computers, the team collaborated with STFC’s Tom Kirkham to access the Hartree Center at STFC Daresbury Laboratory in Cheshire. This enabled them to construct a cloud computing and data processing platform to develop the model. “A real strength of being part of the SFN network is being able to access experts and facilities to support really cutting-edge techniques. It makes a really good platform for research” says Chungui. To train the model, the team collected data from sensors which measured the temperature, day length, relative humidity, CO2 levels, and light levels. The output data included measurements of shoot fresh/dry weight, root dry weight, and leaf area, and photosynthetic efficiency. “The algorithms in the resulting trained model had a strong predictive power, demonstrating that we can effectively extract hidden patterns in these huge datasets to identify the best growth conditions” says Chungui. For their next steps, the team are looking to combine this approach with high-quality, real-time data captured using a state-of-the-art plant phenotyping scanner: the PlantEye multispectral 3D scanner. “These impressive machines can measure a whole range of factors related to plant crop and productivity, including biomass, plant height, 3D leaf area, and greenness– all without having to destroy the plant” says Chungui. Chungui is particularly keen to extend this work to explore tailored ‘light recipes’ for different crops. Plants mainly use the red and blue parts of the visible light spectrum to power photosynthesis, and differences in the relative proportions of these can have a big impact on growth. Since blue light uses considerably more energy than red, working out the optimum recipe can result in great cost savings. Besides productivity, the team intend to investigate how different light combinations also affect flavour and nutritional value. But ultimately, Chungui’s research group wants to see this technology in the hands of farmers, empowering them to make evidence-based decisions. “We are now exploring ‘Smart Green Grow Vertical Farming’ models, where the growing systems have built-in data transfer nodes and communicate with remote data bots to monitor and control environmental and plant performance factors. Ultimately, this would link farmers and their crops together with instant food production enhancement data.” Manure and other organic materials offer a more sustainable alternative to conventional, mineral-based crop fertilisers that carry a high carbon footprint. But our lack of understanding about how these materials interact with soils currently limits their widespread use. With support from the STFC Food Network (SFN), Dr Ruben Sakrabani (Cranfield University) is addressing this knowledge gap so that more farmers can transition to a greener way of crop production. “Producing mineral fertilisers for agriculture requires high amounts of energy, causing it to be a major source of greenhouse gas emissions, and resulting in an expensive final product” says Ruben. In contrast, producing ‘natural fertilisers’ such as compost, manure or slurry, causes fewer greenhouse gas emissions and is generally much cheaper, since many are waste products from farming practices. These materials can also enhance soil structure, increase soil carbon levels, and encourage beneficial microorganisms that support crop health. But there is a key problem against their widespread adoption, as Ruben explains: “A fundamental issue with organic fertilisers is that their composition can vary considerably, making it difficult for farmers to consistently apply the right level of nutrients, such as nitrogen and phosphorus. Whereas mineral fertilisers with similar formulations will essentially be the same, whether you produce them in London, New Delhi or anywhere else in the world” he says. As part of a project funded by Innovate UK, Ruben is helping to develop organo-mineral fertilisers which combine the ‘best of both worlds’: the environmental benefits of organic materials with the consistency of inorganic fertilisers. The research team from Cranfield University have partnered with CCm Technologies, a specialist in carbon capture technology, to trap CO2 from industrial sources (such as a factory chimney) into organic materials. These are dried into pellets that farmers can apply directly to the soil. Nevertheless, incorporating the organic element does introduce some variability between batches. “As long as there is any uncertainty over what exactly the pellets contain, farmers will tend to choose the ‘safer’ option of mineral fertilisers” says Ruben. “But we realised that if this variability can be easily and accurately quantified, it will no longer be an issue as farmers can adjust the amount they apply to the soil. The novel aspect of our work is to investigate whether this can be done with techniques which have never been used for this purpose before.” Through a scoping project grant from the SFN, Ruben launched a collaboration with two researchers based at STFC Rutherford Appleton Laboratories, in Harwell Oxfordshire. These were Dr Genoveva Burca, a neutron imaging and diffraction scientist at the ISIS Neutron and Muon Source, and Dr Sara Mosca, a Raman spectroscopy scientist at Central Laser Facility. Their experiments combined different non-destructive techniques such as neutron imaging and Raman spectroscopy (Box 1) onto the same individual pellets.

“This initial feasibility work demonstrated that these two techniques are entirely workable with the fertiliser pellets, and give an unprecedentedly detailed map of both the physical and chemical characteristics” said Ruben. Whilst Raman spectroscopy defines the chemical bonds present in the pellets, neutron imaging gives information on the humidity distribution and how different particles are arranged.

The team have now progressed to testing their organo-mineral fertilisers in field trials at the Luton Hoo Estate in Bedfordshire, and have just harvested their first crop of winter wheat and winter barley. Promisingly, for both crops using the pellets as a fertiliser resulted in the same yield as crops that were treated with conventional mineral fertilisers. To verify this over the long-term, and to investigate how carbon sequestration is affected, the Cranfield University team have secured funding from Cranfield University and CCm Technologies to launch a three-year monitoring study using oil-seed rape and spring barley. Ultimately, Ruben hopes this research will be applied to develop a simple handheld device that can quickly assess different nutrient levels in batches of fertiliser. “Besides reducing our reliance on mineral fertilisers, our second aim is for this technology to boost yields by helping farmers apply the right nutrients at the optimal time. Plants are like growing children: their development occurs in phases and their needs vary depending on the stage they are at” says Ruben. He is keen to start engaging end-users now, however, and organised a demonstration event at the field study site ahead of the COP26 UN Climate Conference. This was attended by a wide range of interested stakeholders, including researchers, fertiliser companies, farmers, agronomists, water companies and policy makers. “Innovation is all about pushing the frontiers – and that is exactly what we are doing here” Ruben concludes. Reduced food miles, fewer greenhouse gas emissions, less pollution and more resilient supply chains –recovering nutrients in inedible food waste brings multiple benefits, as this SFN-supported project shows. Despite producing more food than ever, around a tenth of the global population (811 million people) were undernourished in 2020 (UN Food and Agricultural Organization, FAO). What’s more, intense agricultural methods contribute significantly to climate change, generate unsustainable levels of pollution, degrade soils, and have led to diets dominated by nutrient-poor convenience foods. On top of these chronic issues, the COVID-19 pandemic has caused major disruptions to the ‘just in time’ food supply model. Consequently, many are now questioning whether we can develop local food networks that are more resilient and sustainable. But with most people now living in urban environments – many miles from farmers and producers – how can we shorten food supply chains on a meaningful scale? The solution may come from adopting Circular Economy principles, where ‘waste’ products are treated as valuable resources and recycled within a closed system. Circular Economy principles can be applied to all kinds of things – from vehicles to packaging – but in terms of food, this means recapturing nutrients from food waste and putting them to work in growing the next generation of crops. This is the ambition of IntelliDigest, a company which aims to support the birth of global circular food systems, which are resilient, robust and capable of feeding the growing global population. “As we build back better from the COVID-19 pandemic, evolving a more sustainable food system is an imperative”, says Dr Ifeyinwa Kanu, CEO and Founder of IntelliDigest. “I love nature and am passionate about engineering solutions to address global challenges, particularly food system sustainability.” Through an SFN 2020 Scoping Project Grant, IntelliDigest was able to work with experts at STFC to advance two projects carrying out the fundamental research needed to support this transition: Turning food waste into crop fertiliser Before food waste can be used in agriculture, the nutrients within must first be converted into a form plants can absorb. Ifeyinwa is leading her team at IntelliDigest to address this using iDigest: an automated bioreactor which uses enzymes from bacteria and plants to turn inedible food waste into a broth-like liquid. The output from iDigest can then be processed into a more sustainable alternative to conventional mineral-based fertilisers (which are by-products of oil and gas processing). In addition, certain recovered biochemicals could be used to produce biodegradable packaging and solar cells, therefore improving the overall food system sustainability. The iDigest bioreactor will have to be capable of handling the enormous variety of food waste that originates from farms, households, restaurants and the catering sector. This will require real-time information on food waste composition, so that the combination of enzymes can be optimised for maximum nutrient recovery. To solve this, Ifeyinwa collaborated with researchers based at the STFC’s Central Laser Facility, at Harwell Campus, Oxfordshire: Dave Clarke, Sarah Rogers and Claire Pizzey. So far, they have explored a range of spectroscopic techniques (including near- and mid-infrared, and Raman Spectroscopy) that may be suitable for developing into a photonic sensor. “We are now building on this work through collaborations with the National Physical Laboratory (NPL) and Strathclyde University, exploring how applying algorithms to the data could give us improved insight on the material characterisation” says Ifeyinwa. The next step will be to develop a simple sensor that can carry out real-time compositional analysis as the iDigest process breaks down complex food waste. As part of the SFN-supported project, Ifeyinwa joined forces with Dr Harry Langford at Crop Health & Protection (CHAP) to run a pilot study on the iDigest broth. The nutrient solution was tested on little gem lettuce, grown either in soil or using hydroponics (where plants are grown without soil, their roots suspended directly in nutrient-rich liquid). Although further work is needed to improve the use of the iDigest nutrient broth in hydroponics, applying it directly to soil resulted in excellent growth and improved nutrient content, compared with using standard commercial nutrient. Potentially, coupling the photonic sensor to algorithms could allow tailored ‘nutrient recipes’ to be produced, optimised to the specific needs of different crops and production systems.

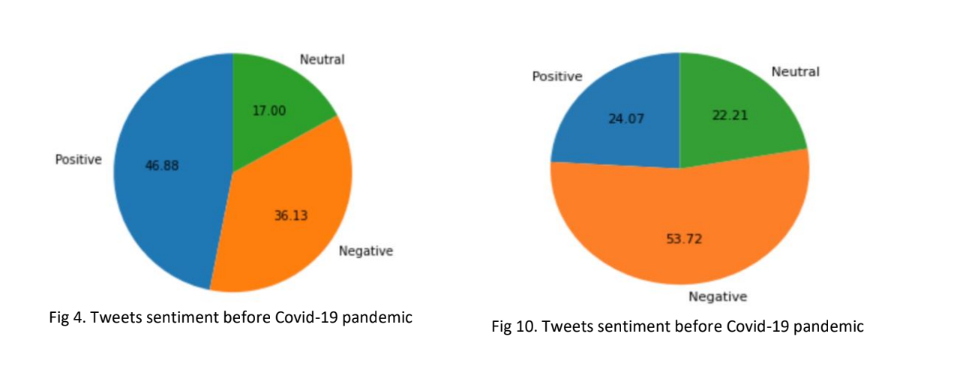

Validating the feasibility of circular farming for urban regions For iDigest to scale up, it will require food waste to be sourced from multiple different locations. Consequently, IntelliDigest is researching a central system for mapping different food waste sources, and ensuring these achieve an overall balanced nutrient composition. In partnership with Dr Jens Jenson, a data mining and machine learning expert at STFC Hartree, Ifeyinwa has developed a pilot interface using the STFC DAFNI platform. Through high-performance parallel computing methods, this presents a logistical and economic model that tracks all food waste sources over a given area. The pilot model was based on synthetic data generated for different potential food waste sources (including restaurants, hotels, schools and households) over a defined region. The resulting model tracks and displays a range of variables, including volume of food waste, frequency of food waste collection, and cost comparisons between recycling the food waste conventionally and the iDigest method. In time, information on nutrient content will be added by linking the food waste source with data from the iDigest photonic sensors. Meanwhile, the platform has sparked a spin-out idea to help ordinary members of the public to reduce their food waste footprint. The Global Food Loss & Waste Tracker (www.WorldFoodTracker.com) is an online platform that allows users to track the volume of their food waste, besides the monetary value and associated greenhouse gas emissions. The platform was officially launched on 18 June (Sustainable Gastronomy Day) 2021 and can be freely downloaded via GooglePlay. “My work with IntelliDigest is exciting because it has the potential to deliver so many of the aims to fix our broken food systems: reduced waste, increased resilience, local food production, more nutritious food, and net-zero agriculture. I am very grateful for all of the support from the SFN and my STFC colleagues” Ifeyinwa concludes. People involved: Food-side CoIs: 1. Dr Devendra Saroj, University of Surrey 2. Dr Elisa Lopez-Capel, Newcastle University 3. Dr Harry Langford, Crop Health & Protection 4. Dr Lydia MJ Smith, Innovation Farm and EA Innovation Hub, 5. Dr Ruben Sakrabani, Cranfield University STFC-side CoIs: 1. Dr Jens Jenson- Data mining and Machine learning (STFC Hartree/DAFNI) 2. Dr Dave Clarke, Dr Sarah Rogers and Dr Claire Pizzey – Infrared sensors (STFC Laser Centre) A project supported by the SFN is bringing to light the problem of counterfeit seeds within African markets – and the best ways to tackle it Every time smallholder farmers sow their fields, they take a gamble that the seed in their hands will germinate well and lead to an abundant harvest. But in Sub-Saharan Africa, many of the seeds on the market are counterfeit or of poor-quality. A wide variety of reasons are behind this, including poor regulation by national governments, insufficient penalties, lack of quality controls within seed companies, and non-standardised labelling. With counterfeit and genuine seed typically being indistinguishable by sight alone, this makes it all too tempting for unscrupulous traders to boost their profits by mislabelling, adulterating or diluting seed. Ultimately, this has significant impacts for the deceived farmers, as Henry Hunga (University of Malawi) explains. “Counterfeit seed results in much poorer germination rates – sometimes as low as 0%, whereas the certification minimum standard is 95% for most crops. Consequently, farmers lose trust in formal seed supply systems, and are more reluctant to adopt seed for improved crop varieties.” This is a major contributing factor to the chronic problem of smallholder farmers achieving yields far below the potential harvest their land could generate. For instance, the average yield per hectare on smallholder farms is less than 1.5 tonnes for maize, 0.8 tonnes for legumes and 2.1 tonnes for rice against a potential of 8, 3, and 6.5 tonnes respectively. Clearly, tackling counterfeit seed could have a tremendous effect in bolstering food security in these regions. But with most evidence on the issue coming from farmer anecdotes, there is a lack of the hard data needed to give governments an incentive to act. In addition, poor understanding of how counterfeit seed enters the market has made it difficult to judge the points where interventions would be most effective. As part of a project supported by the SFN, Henry has started to address this. “Our objectives for the project were two-fold. First, to prove that there are indeed counterfeit seed on the market. And secondly, to map the seed supply chain and identify hotspots suitable for intervention” Henry says.  Laboratory at a seed company responsible for internal quality control - Credit: Henry Hunga Laboratory at a seed company responsible for internal quality control - Credit: Henry Hunga Capturing the scale of the problem: To understand how common counterfeit seed are, Henry and his colleagues used a mystery shopper approach to source 47 samples of maize seed from markets and trading centres across Malawi. The team then performed DNA sequencing to quantify the level of genetic variation both within the samples, and between the samples and reference seed from certified companies. This was followed by additional quality control tests, including for moisture content, germination and vigour.  Seed delivered to seed company from farm for processing (quality testing, sorting and packaging) - Credit: Henry Hunga Seed delivered to seed company from farm for processing (quality testing, sorting and packaging) - Credit: Henry Hunga "Rather shockingly, the results showed that only one sample from the market dealers matched the reference seed. None of the rest matched either the reference or similar varieties from different dealers” says Henry. “This clearly demonstrates that counterfeit maize seed is truly a serious problem within Malawi.” Having unequivocally confirmed counterfeit seed within the Malawi market, the next stage will be to quantify how widespread they are, including for other crops. “We also intend to establish a DNA reference library that can be accessed by stakeholders, which would significantly cut the time required for measuring genetic variation between samples” says Henry. Identifying strategic interventions: In parallel to the DNA sequencing work, the team also conducted a mapping exercise to identify which points along the seed supply chain are hotspots for counterfeiting activity, and should be targeted first. This involved visits to producers, multinational and national seed companies, markets and agrodealers in Lilongwe, Mchinji, Dowa, and Ntchisi districts in Malawi. “Our preliminary value chain mapping showed that most seed companies do not have internal quality control systems, and rely on public regulators who are often overwhelmed. Another major challenge came from dealers who fraudulently access company packaging materials, or produce counterfeit versions, then dilute or adulterate the actual seed” Henry says. But these could potentially be tackled by innovative, new technologies – such as Blockchain. A Blockchain [CW2] is essentially a digital ledger of transactions that is shared across all the computer nodes within the chain. Each new transaction is recorded on every participant’s ledger, making it very difficult to hack or change the data. “The distributed ledger system means data is not managed by individual stakeholders, making it tamperproof. This gives increased security, besides the ability to trace and share information across all stakeholders in real time” Henry says. Ultimately, Blockchain could enable batches of seed to be tracked right from production through to processing, markets and finally the farmers themselves. “Blockchain also has the advantage that it does not have to be regulated and maintained by governments. Preparing the private sector to be involved in the regulatory process is one of the best strategies for future interventions” Henry adds. But for Blockchain to be a success, it must be understood and accepted by the end-users themselves, so the project team also conducted stakeholder workshops with representatives from private seed companies. “The participants showed a strong interest in using Blockchain, and felt it was better than current traceability systems, such as verification codes, which are limited by the proprietary nature of data, and the fact they can be manipulated by individuals.” Henry now hopes to develop a proof-of-concept preliminary Blockchain platform for the Malawi seed supply chain. “Ultimately, we expect to link this Blockchain technology to DNA testing, so that seed companies and public regulators can verify that seed from producers is the true genetic material of the proclaimed seed variety” he says. If this goal comes to fruition, Henry’s work could help thousands of smallholder farmers achieve more consistent harvests. Yet the project has also helped him develop on a personal level, thanks to the support from the SFN: “Through the SFN, I have been able to work with a diverse team of experts, both locally and from the UK, and have also participated in several career development and networking activities. I am very glad to be part of the network, and hope to work with them further as we take this project forward.” Find out more: see our blog post on an SFN project using Blockchain and Internet of Things technologies to digitize Chinese food supply chains Henry would like to thank his UK-based co-investigators for their guidance and support during the project: Dr. Jens Jensen (STFC) Dr. Tom Kirkham (STFC) Dr. Jayne Crozier (CABI, UK) Dr. Sachin Kumar (University of Plymouth, UK) Dr. Manoj Dora (Brunel Business School, UK) Dr. Jan Mei Soon (University of Central Lancashire) A project supported by the SFN is researching how to turn microalgae into a nutritious, useful and – above all – tasty food product  Could microalgae be a food for the future? - Credit: Yixing Sui Could microalgae be a food for the future? - Credit: Yixing Sui We are all too aware that our conventional agricultural systems are having devastating impacts on our planet. This has sparked a strong interest in more sustainable ‘alternative’ foods – from ‘lab-grown’ meat to insect-enriched flours – but these can only make a difference if consumers accept them. And for that to happen, novel foods need to be affordable, easy to cook with and, perhaps most importantly, appealing to our taste buds. Dr Yixing Sui (University of Greenwich) knows this only too well. “Even if you have a perfect food product that is both sustainable and healthy, you have to pay attention to the end-user because it will be of no good if the market doesn’t accept it.” The particular food he is trying to get on our plates is microalgae. This term includes both photosynthetic cyanobacteria and small, plant-like organisms on the single-celled scale. Individual microalgae can’t be seen without a microscope, but when they multiply in their thousands, they produce dense cultures of beautiful colours: green, orange, red or blue-green, depending on their pigments. As part of a long-term project supported by the SFN, Sui is researching how to turn this unappetising sludge into palatable food products. “We call it a novel food product, but microalgae has historically been eaten in Africa, Asia and South America” says Sui. The Aztecs, for instance, were recorded collecting mats of Spirulina species to make into dry cakes, called tecuitlatl. “Nevertheless, microalgae never became widespread across the modern world due to their having a very strong, fishy taste and smell, which most find off-putting.” With this in mind, why should we bother trying to eat it? First of all, microalgae have very strong nutritional credentials. “Microalgae species generally have high protein contents, with a profile that covers all the essential amino acids (for humans), comparable to soya, milk and eggs” says Sui, who for his PhD thesis researched how amino acid content in microalgae varies depending on their environment. “By changing the cultivation conditions, you can boost the level of a specific amino acid even further, without affecting the others.” Farming microalgae also has fewer environmental impacts than conventional protein production systems, since they are highly resource- and water-efficient, and can generate a harvest within weeks – significantly quicker than the annual cycles for most crops. There is also the advantage that microalgae can be farmed anywhere, as Sui explains: “All you need is sunlight, a warm temperature and an open pond or photobioreactor. This opens up the possibility of growing microalgae using land that is currently unproductive, such as deserts.” But for microalgae’s benefits to be realised, we need to first overcome the taste barrier. To address this, Sui and his colleagues are researching how flavour compounds vary across different species, and whether these can be manipulated to make them taste better. As part of a SFN Scoping Project, he joined forces with Dr Geraint Morgan (The Open University), who has a track record in applying highly-advanced analytical techniques to new sectors, including the food industry. The team initially focused on identifying glutamate and aspartate, two compounds that give the umami taste - the savouriness we associate with foods such as cooked meats, tomatoes, mushrooms, cheese and broths. Rather than choosing a microalgae species from the Spirulina and Chlorella genera (conventionally used for human consumption), they selected Dunaliella salina, a species that is already widely farmed to produce β-carotene. Nevertheless, D. salina is also protein-rich, with an amino acid profile that matches human requirements. “Our first objective was to establish if microalgae do contain umami compounds at all” says Sui. “The second was to understand how these are balanced with compounds for other flavours, including bitterness and earthiness, to see if the overall profile could be tweaked to resemble something more like mushroom-meat.” The project uses gas chromatography, a technique for separating and identifying different compounds. “The samples are heated and vaporised in the gas chromatography instrument, and the gaseous compounds travel through a matrix material” says Geraint. “The distance that the compounds travel through the matrix before being adsorbed to it depends on their chemical structure – we call this the retention time.” The compounds can then be identified by comparing the retention times with those in reference libraries. In previous SFN Scoping Projects, Geraint has demonstrated how gas chromatography techniques can be applied to the food sector, including in ‘sniffing out’ rotten avocados from unblemished ones, and predicting the shelf life of bagged salads. Whilst the results confirmed the protein potential of D. salina, the team only detected low levels of glutamate and aspartate. But unexpectedly, through follow-up work supported by ValgOrize (a European project funded by the Interreg 2 Seas programme) they found that D. salina is unusual in having an overall sweet and floral flavour, rather than a fishy one. “We checked the results by sending samples to be tested by panels of trained human tasters at the Flanders Research Institute for Agriculture, Fisheries and Food . These found that this microalgae has a very different taste profile compared with Spirulina and Chlorella” says Sui. The challenge now is to identify these compounds, and then work out how both production and cooking processes can be optimised to enhance these as much as possible. “Since the biochemical composition of microalgae is so dependent on the environmental conditions, developing this analytical capacity further will be crucial to finding out the best cultivation techniques” says Sui. Consequently, he is keen to continue working with the SFN and has been awarded a proof-of-concept grant from the Network. This will involve experimenting with D. salina as a food ingredient, and tracking the changes in nutritional and taste profiles before and after cooking in order to identify the most suitable food products to use it in. “There are a wide range of potential uses, including noodles, cupcakes and even as an egg replacement in vegan versions of products such as mayonnaise and pastry. But this will depend on other properties besides taste, including structure and texture” says Sui. It may be a while yet before many microalgae-enhanced foods appear on our supermarket shelves, but in the meantime Sui has already started experimenting, using commercial D. salina powder sourced from Australia. “I used the powder to make cookies, and whilst they were a bit green they definitely didn’t have a fishy smell!” Find out more: Read our blog post on a SFN-supported start-up bringing another novel aquatic protein source to market: Lemna, a water plant that looks unremarkable, but could be a highly sustainable food for the future. The COP26 Summit in Glasgow was not the only gathering on climate change that took place last month: the SFN hosted its very own virtual COP26 festival, with events held throughout 2 – 5 November "The aim of this was to celebrate and showcase how STFC capabilities have made a meaningful contribution to global food systems” says Alison Fletcher, Project Manager & Network Coordinator for the SFN. “But we also hope the festival will have a longer-lasting impact, by creating an online resource that helps food systems researchers to identify how STFC technologies could help their projects.” The festival programme included a panel discussion and webinar, which both attracted diverse audiences that included representatives from academia, major food companies, governing bodies, food businesses and agricultural consultancies. For those that missed them, the full-length recordings of both events are available on the dedicated festival webpage, alongside a virtual exhibition and interactive map of SFN projects. Expert panel discussion: Innovations for Carbon Neutral Food Systems The webinar Innovations for Carbon Neutral Food Systems explored how the agricultural sector’s sheer complexity makes it imperative that efforts to cut its greenhouse gas (GHG) emissions use a holistic, multi-level approach. This will require action from all stakeholders, and policy makers will naturally have to lead the way said Dr Erica Pufall from the UK’s Food Standards Agency. She outlined a number of options for initiating positive change using policies, from taxing GHG-heavy food products and addressing food waste, to incentivising sustainable production practices and helping farmers to access innovative precision technologies. The financial sector – often portrayed as ‘the bad guys’ – will also have a crucial role, explained Dr Chris Cormack (Quant Foundry), a global leader in modelling the financial impacts from climate change-related risks. Considerable investment and capital will need to be mobilised to facilitate the transition to a net-zero world, but this can only happen if the financial sector and policy makers work together to build new, global carbon markets driven by accurate, well-audited data. But individual actions and choices also count, and Dr Christian Reynolds (Centre for Food Policy, City University, London) was optimistic that we can build on the increased consumer awareness of ‘planet-friendly’ diets to empower people to adopt more sustainable habits. Webinar: STFC Instrumentation for Sustainable Food Systems The STFC is host to some of the UK (and the world’s) most advanced scientific instruments, including the UK’s national synchrotron, the Diamond Light Source; state of the art, high-energy lasers; and facilities that can simulate outer space conditions. But since these are typically used for astronomy, physics, and space-related research, the food sector is generally unaware of these capabilities. A core purpose of the SFN, therefore, is linking up STFC technologies with food-systems researchers and businesses to spark truly novel approaches that haven’t been tried before. These collaborations allow food-sector researchers to perform experiments and analyses that would otherwise be beyond their means, such as big data and machine-learning methods; hyperspectral imaging; and neutral and gamma material assays. In return, STFC technicians and researchers have an opportunity to apply their expertise to a completely different area. The webinar STFC Instrumentation for Sustainable Food Systems showcased a series of impactful SFN projects that perfectly illustrated this in action. For instance, Dr Hugh Mortimer (STFC RAL Space) described how his involvement in SFN projects had allowed him to apply his expertise in hyperspectral and thermal imaging (developed for Earth Observation analysis) in new ways, from diagnosing diseases in trees, to soil analysis and tools to optimise apple harvests . The event also featured Dr Anthony Brown (Durham University), who described the potential for unmanned aerial vehicles in the food sector, including to monitor soil moisture content and track the spread of deadly crop diseases. Meanwhile, Dr Maria Anastasiadi (Cranfield University, UK) spoke about how spectroscopy-based techniques could help tackle food fraud, using the example of monofloral honeys Interactive map of SFN projects This new feature illustrates at a glance the reach of SFN projects, both on a UK-wide and global level. Even those who have long been involved with the network will likely be surprised at the truly international nature of the projects supported so far. “As a tool, it will particularly help people new to the SFN to see the kinds of projects we have been involved in so far’ says Alison. ‘The filters make it easy to search projects based on either different STFC capabilities (for instance, data science) or food intersections (such as consumer behaviour and nutrition).” SFN COP26 Hackathon This four-day competition was inspired by the urgent need to help smallholder farmers adapt to climate change by providing up-to-date, location-specific data to advise them on the crop types and varieties they should grow. Teams of designers, coders, scientists and data analysts were challenged to create an open access platform that could integrate highly varied datasets – from soil maps to market price data – to recommend crop type, planting date and management regimes, specifically for smallholder farmers in India. You can learn more about the event and the winning entries on our blog post.  Agrifoods Innovations Exhibition With visual communications becoming increasingly dominant in our digital world, the SFN team decided to curate a virtual gallery of arresting images to readily illustrate the individual and collective impact of SFN projects so far. The exhibition represents approximately half of the projects funded to date, and will be added to over time. Throughout the COP26 festival, the images were used in a social media campaign to encourage viewers to click through to read more information about the illustrated project. “Ultimately, we’d also like to use the images to create collages for pop-up banners and posters at future events. This will draw in people who are curious to learn more about the projects behind the images, and present an opportunity to introduce them to what the SFN does” says Alison. All the resources from the SFN Virtual Festival for COP26 can be found on its dedicated webpage.

|

AuthorJune 2024 - Archives

June 2024

Categories |

- Home

- Webinars and Events

- About the SFN+

- News

- Blog

- Expert Working Groups

- Funding

-

Publications

- Bioeconomy positioning paper

- SFN+ 5th Annual Conference

- OMM Policy Report

- ‘Multi-Stakeholder International One Day Workshop on Organic Agri-Food Value Chains for Net Zero’ Report

- SFN 2050 UK Net Zero Food report

- Sustainable Cold Food Chain Booklet

- Food Sensing Technologies for Safe and Nutritious Food

- Sustainable urban and vertical farming

- Projects

- Join/Contact Us

RSS Feed

RSS Feed